AGV , Conveyor , Transportation , equipment

・reassuring for underfoot by flat-top.

(Inspection・Sign boarding・Re-stacking work)

・Smooth delivery by multi-speed shifting function.

・No cargo-collapse at long distance transport.

・No oil adhesion to products by non-oiling.

・Accumulation, Data-tracing by PLC control.

Steam removal is also possible.

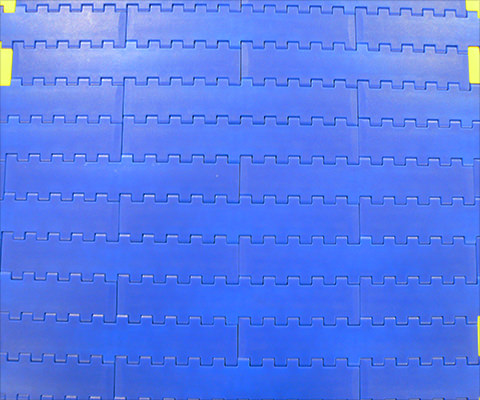

・Modular belts

・Stabilized conveyance

・1 inch・flat top(closed hinge)

Polyacetal resin

・Tensile strength30000N/m

・Roller top belt, outstanding durability.

・Accurate conveyance by multi-roller.

・no-catching with flattened top surface.

・Safety work by internal built-in of lifting parts.

・Sheet direct conveyance.

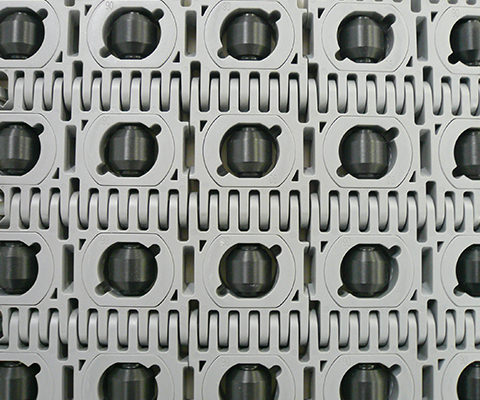

・Modular belts

・Stabilized conveyance

・2 inch・Roller top (Angled roller belt)

・Tensile strength23000N/m

・Conveys to 90°direction.

・Thin width belts lifting.

・Belt 450mm pitch

φ57・φ42 drive roller+Free roller combined

・Less vibrations by flat rail.

・Transmission of large amounts of information by

wire-less LAN.

・Doubled conveyance capacity with 2 stacks transport.

・Ensuring safety with laser scan sensor

(1)Underlay-paper inserter

Inserts underlay-paper to products while being conveyed.

Protects sheet at bottom from stains even when directly-conveyed.

Insertion of underlay-paper while being conveyed prevents cycle time interruptions.

Corresponds to plastic card board. It is re-usable.

(2)Underlay-paper pallets

Place the underlay-paper automatically on the pallets.

Reduces worker burden.

(3)Top-sheet device

Places top-sheet on top of products.

Protects products under when stacking on the products.

Reduces worker burden.

・Stacker ability 100% by off-line work.

・Increases pallet load efficiency by

separation/coalescence of sheet stack.

Pallet types can be reduced.

・15sec. cycle by 2 device linked structure.

Plastic pallet・Wood pallet・Plastic veneer・Wood veneer, any materials are usable.

Realizes accurate and stable conveyance by selecting flat-top modular belt or grip-top modular belt according to applications.

adsorption type・fork lift type・pusher type, we will respond with optimal system.

・30 pallets storage by stocker equip.

・High-speed operation of 15sec. cycle supply by 4 hook

separated drive.

・Certainly supplied by modular conveyor.

Realizes stabilized transport with 2-way only conveyance, unlike free-directed conveyance of ball conveyor.

It suits to pallet/veneer loading conveyance.

Fully automatic・Fully-driven is not always necessarily for the factory.

In the lateral direction, it is driven and conveyed by an electric motor electric motor.

The roller direction (vertical direction) is hand-push conveyance.

Efficiency and cost reduction of complicated work have been realized by combination of latest belt and hand-push work.

We will make proposal according to unique circumstances of factory.

Travels identical rail. Main transport is depended on electrical trolley. Detailed works such as product replacement is performed by hand-push trolley. Improvement of work efficiency. Refrains from interfering electrical trolley`s work range by folded storage when not in use.