AGV , Conveyor , Transportation , equipment

Simple and logical line that corresponds to need of multi-product・small lots in cardboard factory. Ideal line for pursuing productivity which responds to high-speed processing and increasing operation rate of corrugate machine. Furthermore, it is the highly durable Paper roll transport system that increases efficiency. GODO`s Paper Roll Transport System, GO-RIDER. Currently, this system is implemented in numerous cardboard factories receiving high accolades and a proven reputation.

Our track record has more than 93 successful implementations since started to deliver in 1995.

It is completely linked with corrugate machine, simply set the base paper in the tilted storage to supply it to the Mill Roll Stand and carry out the remaining rolls. By fully automatic system, it reduces personnel involved in transporting a paper roll and operators are enabled to devote more time to the corrugate machine.

There is no need to worry about fire.

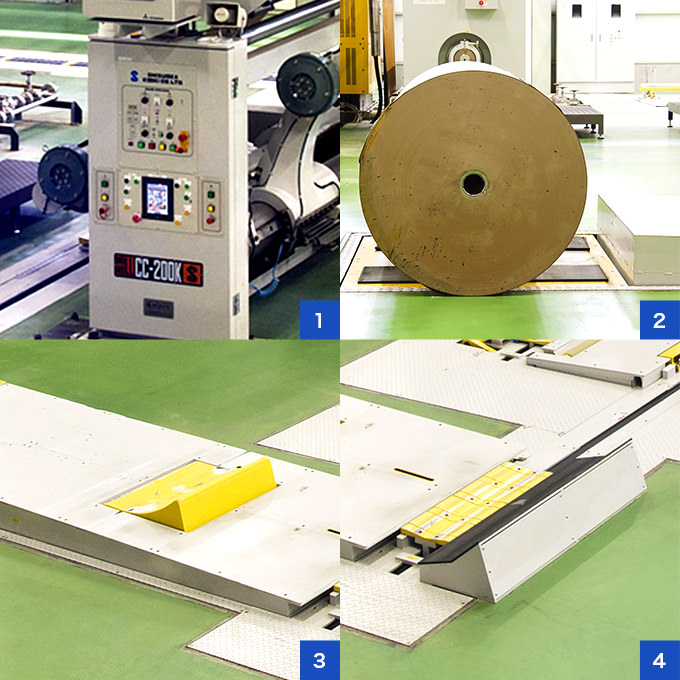

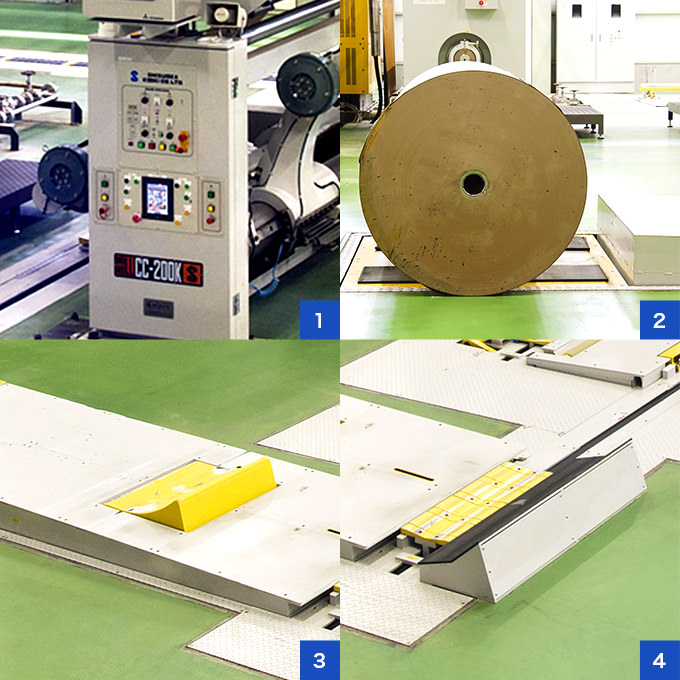

Operation panel

Fully automatic controlled by turning switch to “Auto” which links with mill roll stand.

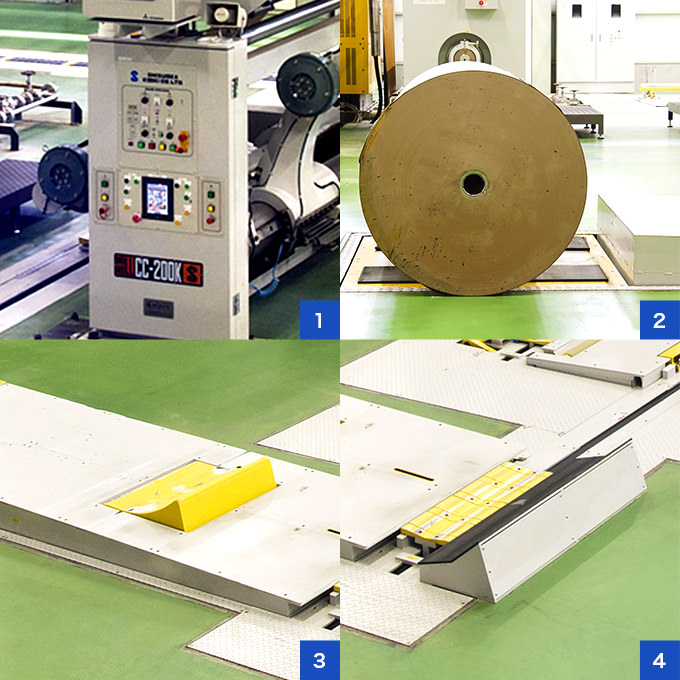

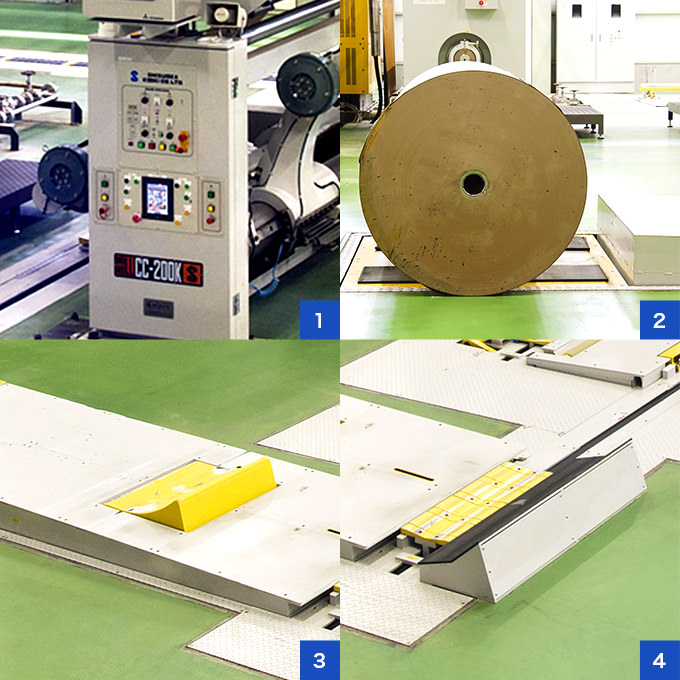

Inclination lifter

Because the lifter is liftable manually, paper roll is loadable on the storage without clamp-car.

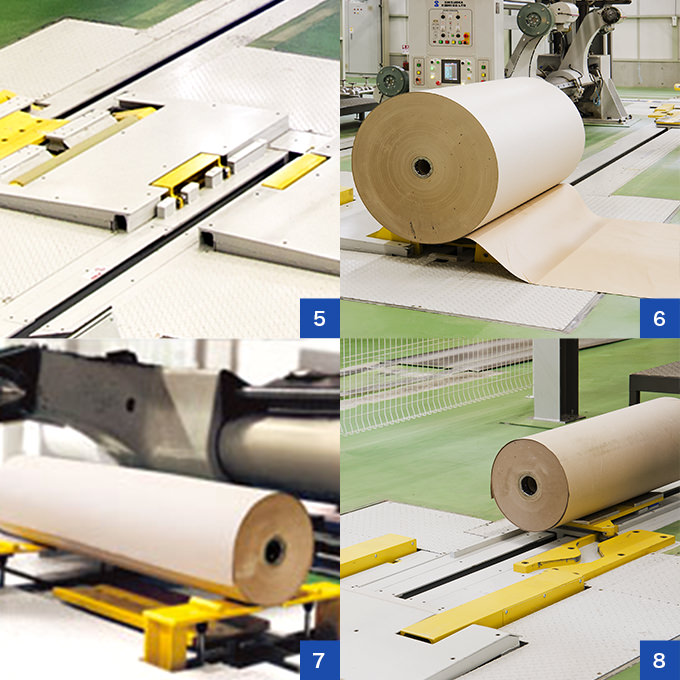

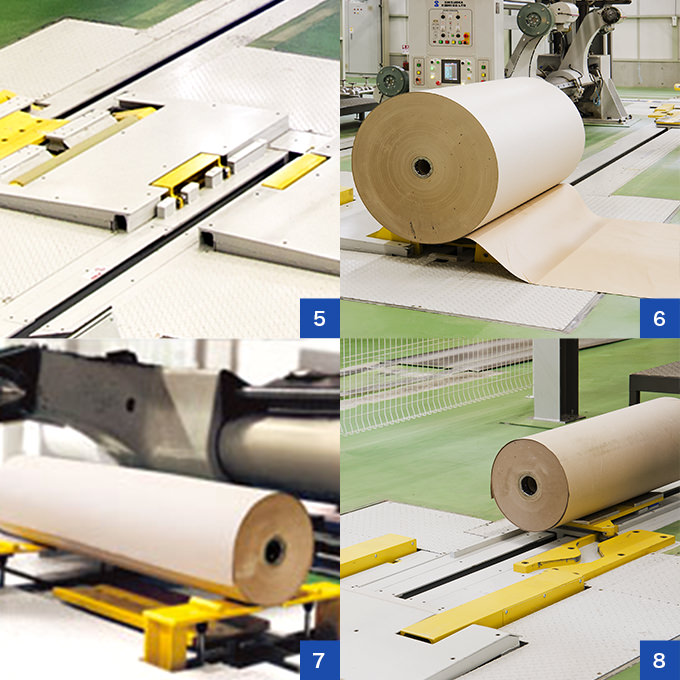

Inclined storage

Due to inclination of storage, when clamp car places paper roll on the storage, it is transported to dolly 1by1 .

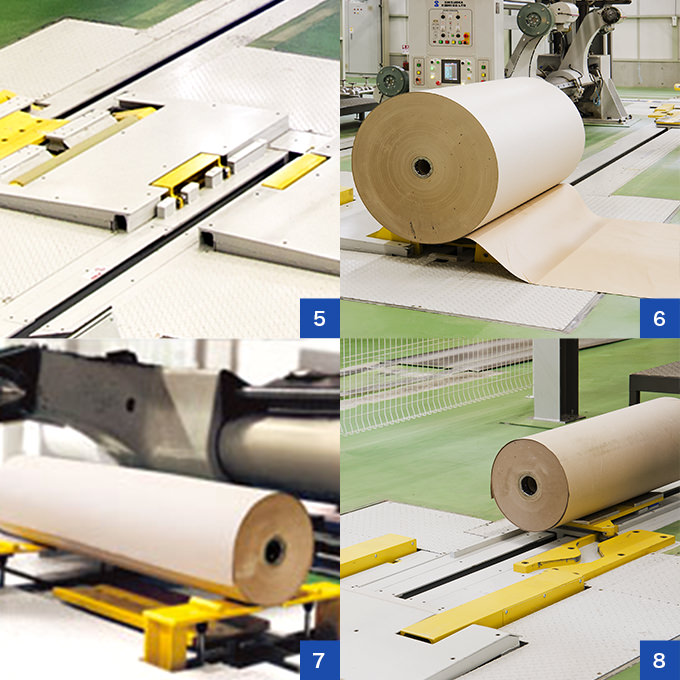

Sub lane

Set the paper roll on the dolly to pass through the sub lane, and transports to right and left distribution dollies.

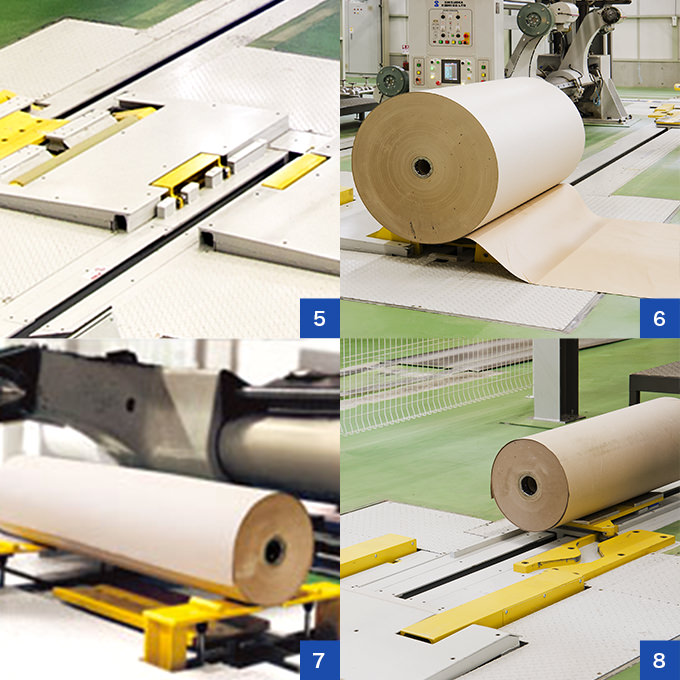

Right and left sorting section

Sorts paper rolls to right and left, and places on the carry-in dolly.

Main lane

Correction of paper roll, and assists peeling. Performs centering by measuring roll length, and roll diameter.

Small-diameter roll lifter

When the small-diameter roll is under 400mm, lifter will lift up to enable the Mill Roll Stand to catch automatically.

Turn traverser (Carry-Out dolly)

Carry-out dolly will wait at the center of Mill Roll Stand and receive the remaining roll. Dolly rotates 90 degrees while traveling through the unloading lane, transfers rolls to conveyor by unloading transfer lifter.

Returning conveyor

Transports remaining roll which transferred from each line to kicker.

Kicker

The remaining rolls transferred from each line are placed and transported to the kicker. The final line of the transport system that pushed out the remaining rolls in one place and carries them out. Work efficiency is improved because the clamp car are positioned in one line making it easier for collection.